To begin with, GD&T symbols are standardized and defined in the ASME Y14.5 requirement, which implies they have global acceptance in engineering self-controls. Flatness, represented by a two-dimensional icon, guarantees that a surface is evenly flat within defined restrictions, which is essential for surface areas that require to secure or mate.

Discover GD&T symbols and guidelines the value of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it boosts communication, accuracy, and cost-efficiency while lessening errors via standardized symbols and guidelines.

Along with develop controls, GD&T also consists of positioning controls, such as similarity, angularity, and perpendicularity. These symbols determine just how much a function must straighten with respect to an information recommendation. A perpendicularity control specifies that a surface area must be at an ideal angle to another surface within a specified tolerance. Such controls are essential in assemblies where exact alignment is required, such as mechanical parts in a transmission system. Understanding exactly how to specify and translate these alignment symbols is pivotal for exact manufacturing and quality design.

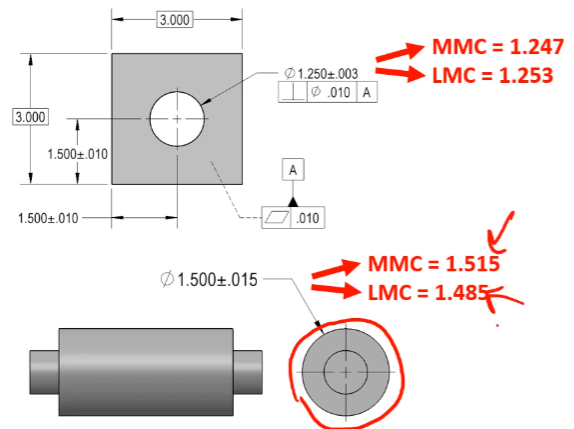

Area controls such as setting, concentricity, and proportion are additionally vital facets of GD&T. Positioning a function properly is crucial in making sure that components can be assembled effortlessly. The placement symbol, as an example, makes certain that holes or slots are located at specified collaborates within a specified tolerance zone. Concentricity is made use of to ensure that cylindrical attributes are aligned along an usual axis, which is particularly vital in applications requiring rotational proportion. Learning to apply these place symbols effectively will aid designers in attaining practical components that meet style specifications while likewise streamlining the manufacturing processes entailed.

Another critical facet of GD&T is the principle of information, which are referral factors or surface areas that offer as a basis for dimension. Correctly defined datums enable engineers to regulate variants extra properly, reducing the opportunity of mistakes in production.

When a designer defines tolerances making use of GD&T symbols, it minimizes the uncertainty often connected with conventional dimensioning approaches. In markets where precision and high quality are critical, such as aerospace or clinical gadget production, the function of GD&T in streamlining interaction can not be overstated.

In addition, the application of GD&T is useful for expense efficiency in production. By defining resistances much more properly, engineers can maximize styles to use procedures and materials better. For instance, by specifying bigger tolerances where limited tolerances are unneeded, manufacturers can make use of less pricey machining methods, conserving both money and time while still keeping the integrity of the last product. This effective strategy helps alleviate waste and reduces manufacturing costs, which is crucial in today's competitive market. Engineers that master GD&T can substantially influence the cost-effectiveness of their styles without giving up quality or efficiency.

Lots of educational resources, workshops, and training courses are currently readily available to aid engineers and designers find out the subtleties of GD&T. Practical applications of GD&T in instance researches can provide insight right into just how effectively implemented symbols lead to improved high quality and minimized scrap prices in production.

When editing or interpreting engineering drawings that make use of GD&T, focus to information is vital. Standardization advertises a society of high quality and consistency, strengthening the value of GD&T concepts in daily engineering practice.

Discover mmb vs mmc the importance of Geometric Dimensioning and Tolerancing (GD&T) in engineering and production, as it boosts interaction, accuracy, and cost-efficiency while lessening mistakes with standardized symbols and guidelines.

In verdict, grasping GD&T symbols and guidelines is an important skill for modern-day engineers, specifically those included in design and production. By spending in proper training and exercising the efficient application of GD&T concepts, engineers can leverage this effective tool to drive technology and quality in their designs, inevitably leading to a much more successful and affordable product growth lifecycle.